TUBE MILL LINE

[/cz_title]

- Quality

- Efficiency

- Service

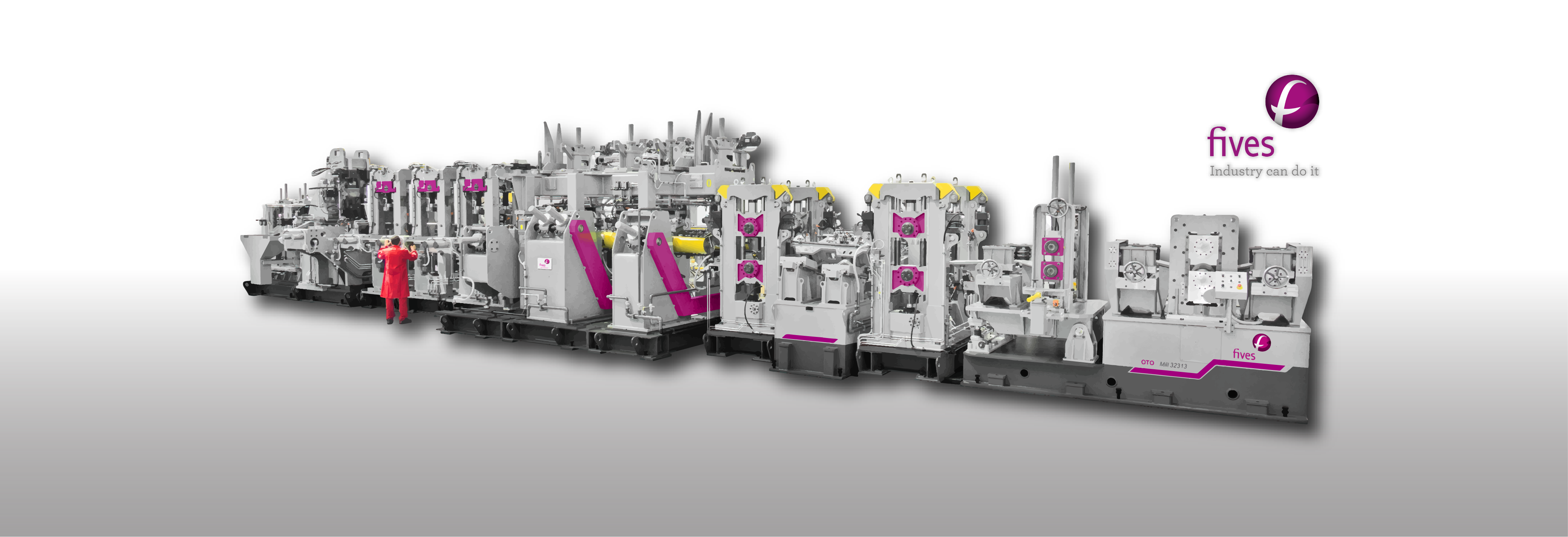

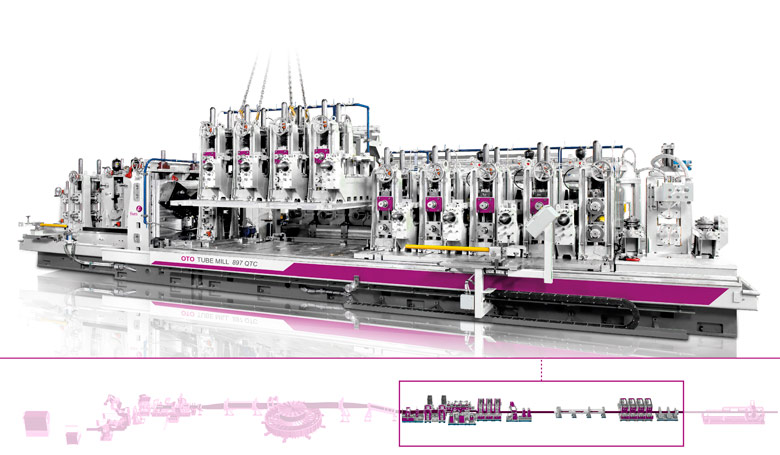

Precision and efficiency in its complete range of electric resistance welding tube mills (ERW mills) under the historical names Abbey and OTO. Catering to carbon and stainless steel ERW tube production from 4mm – 762mm diameters with wall thickness from 0.4mm – 28mm, High quality standards and advanced manufacturing techniques guarantee functionality, safety and productivity. The tube mill lines feature fastest changeover system, enabling higher productivity and significant downtime reduction.

Not only selling, But also planing, consulting, and giving the best solution.

CREATIVE AGENCY

VIEW ALL PROJECTS

BUSINESS SOLUTION

VIEW ALL PROJECTS

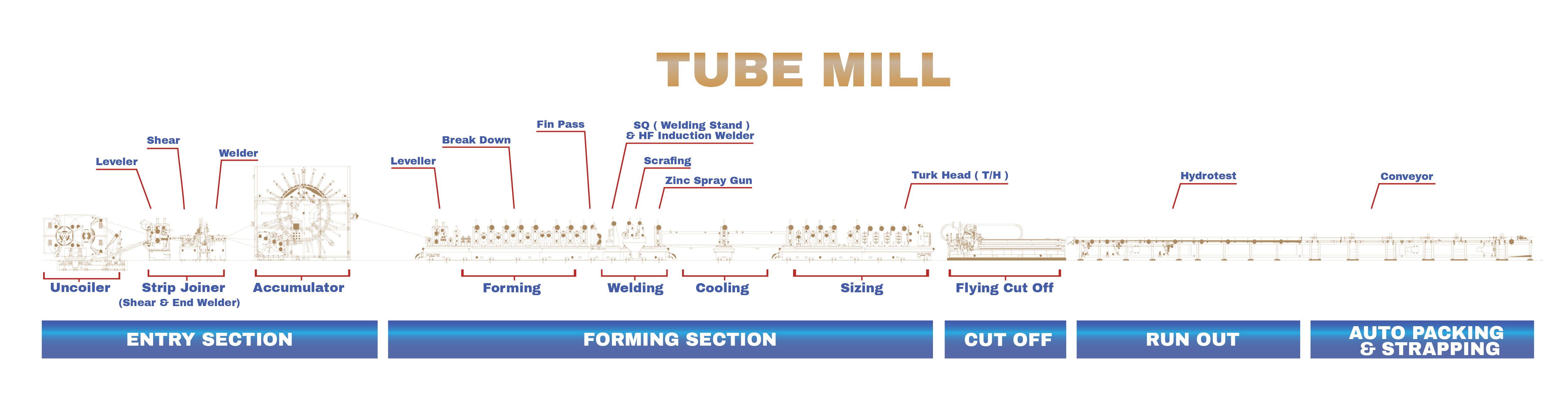

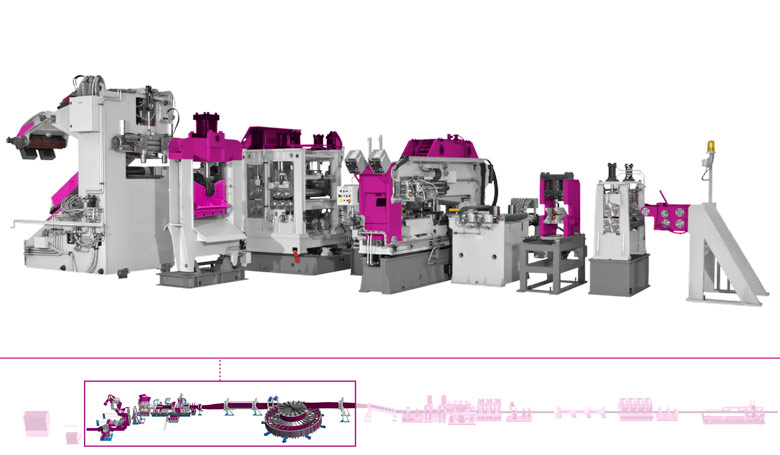

SCHEMA TUBE MILL & LINES

Takeco Engineering

MACHINE OF TUBE MILL LINES

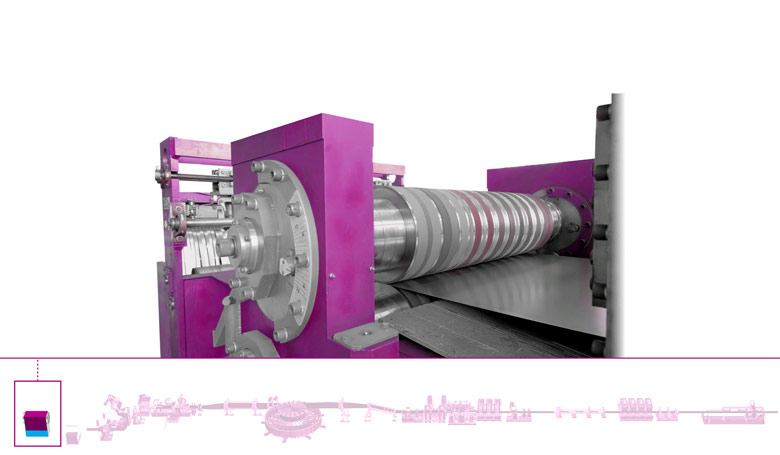

heavy-duty Abbey slitters for low carbon and stainless steels. They feature robust design and quick change heads. The largest will slit coils up to 45 metric tons and 2,790mm wide.

They include automatic edge control, injector or lift-off slitting heads, scrap winders or choppers, tension stands, and many other features.

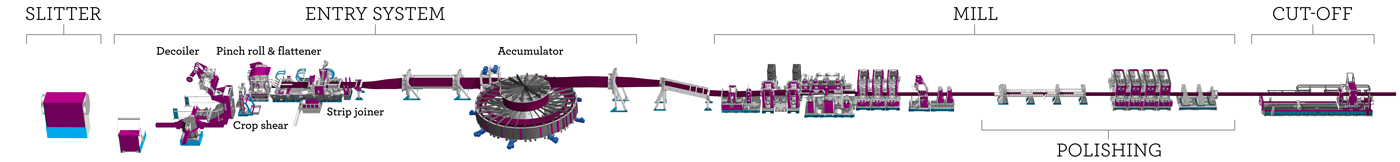

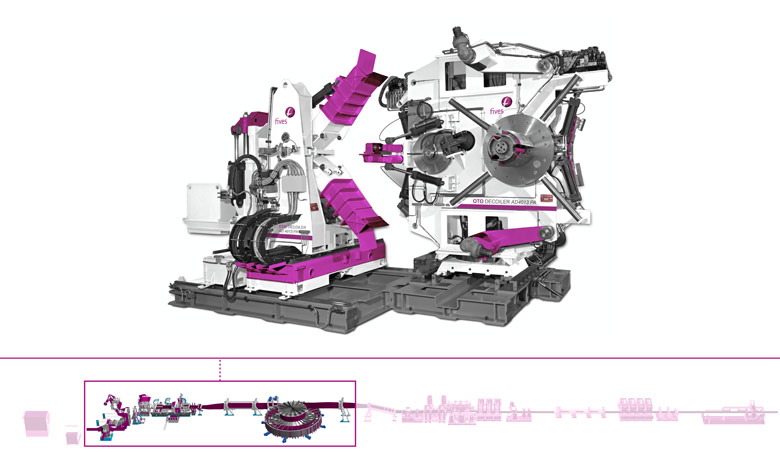

entry system utilizes innovative technology to feed strip to the tube mill. It includes an automatic coil loading system, a decoiler, a pinch roll and flattener, a strip joiner and a accumulator. The entry system configuration can be manual, semi-automatic or fully automatic.

Each configuration of the equipment is designed to guarantee high strip quality while ensuring operators’ safety.

designed to support a range of strip widths and thicknesses. Available with manual or fully automatic coil preparation, these machines are robust enough to support the heavy coils as they are unwound at speed. Each model is low maintenance and designed with safety in mind.

reliable joining of steel coils for strip widths from 30mm – 2400mm and thicknesses from 0.4mm – 28mm. Manual, semi-automatic and automatic models are available to precisely trim and join the strip. The automatic strip joiner includes control of strip end position, feed into the clamps, trim of strip ends, weld cycle, bead milling and release. Controls are integrated in the PLC.

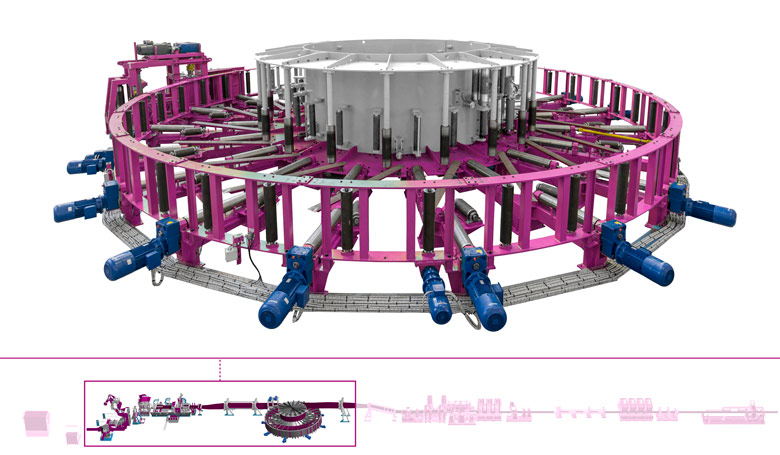

low-maintenance strip accumulators deliver high speeds and high accumulation capacity without compromising on the careful strip handling required by high quality materials.

The strip accumulators integrate fully with the tube mill system so end shearing and welding can be carried out while the tube mill runs at constant speed.

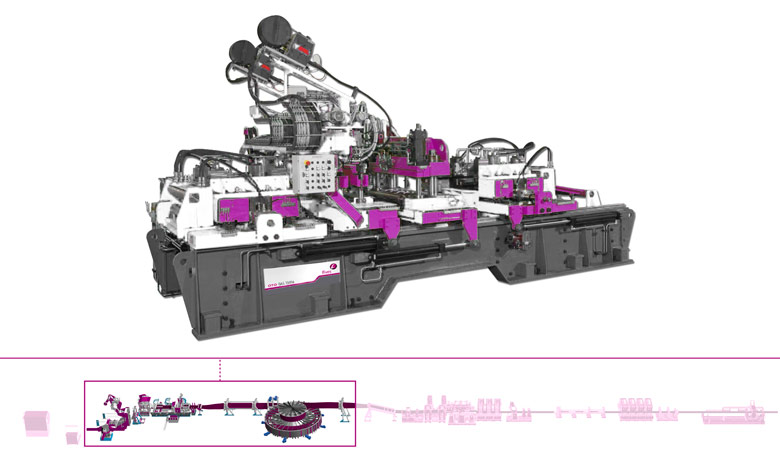

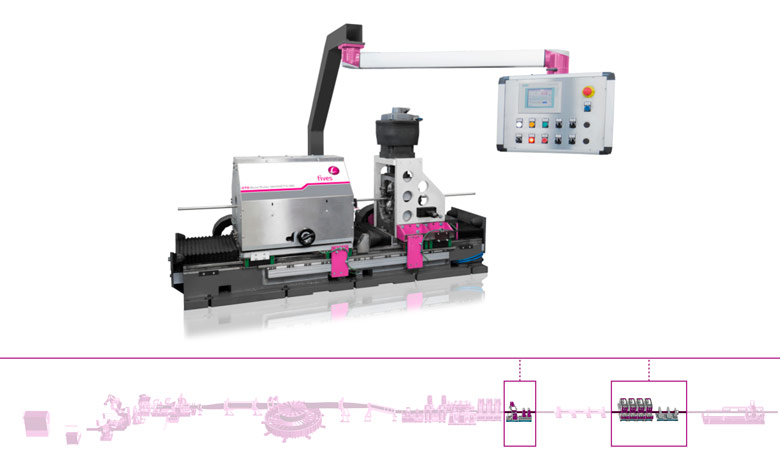

laser or TIG mill forming technologies for different tube diameters and thicknesses, as well as various changeover systems: completely automated with software controlled roll adjustments.

A wide range of polishing solutions for laser, TIG and HF welded stainless tube and pipe: internal magnetic beaders, external scarfers and brushers for round tubes and hollow sections.

The offer inlcudes a revolutionary technology: magnetic internal bead systems with patented permanent magnet housing. It delivers precise process control, resulting in a smooth rolling process and very low rolled material roughness.

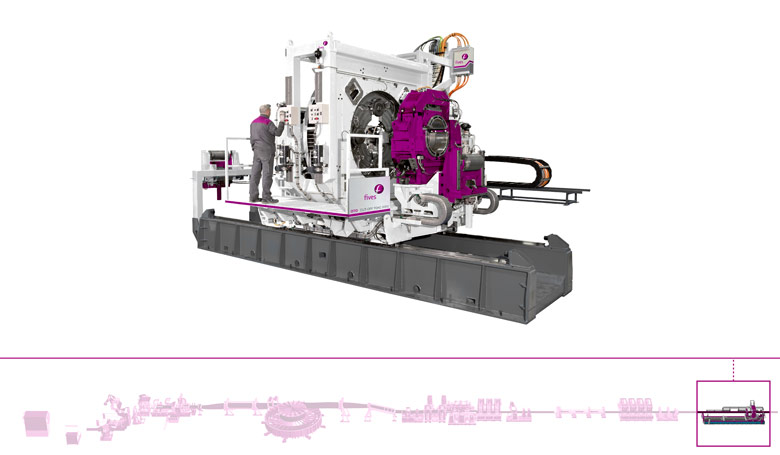

Whatever your process requirements, has a OTO flying cut-off to suit you. With more than 20 models available, the perfect cut-off technology exists according to your tube size, material type and performance requirements. Choose from cold saw, laser, bandsaw and other types of cut-off technology to find the right machine for every application. Each cut-off system is designed for high thrust force, maximum quality, precision and reliability.

We offers a full range of packaging machines for round,square and hexagonal bundles. Our tube handling and the packaging machine operation take place automatically in order to meet the maximum production capacity, high production speed,hogh product quality, low labor cost, the noise reduction as well as the optimum safety standards for the operators involved. Our packaging lines are designed in a way to be integrated with automatic and/or manual strapping units, labeling, wrapping units, weighing and final warehouse area

Automatic strapping machine is designed for heavy-duty strapping applications. Strapping machines which suit all applications and all budgets. We offer a full range of fully automatic, automatic, and semi automatic strapping machines that utilize our famous Flexband polypropylene strapping. Semi automatic strapping machines are the most economical choice; a great addition to any mail room. Polychem’s automatic arch machines are extremely reliable and also come in side seal, dual press, small package, and stainless steel configurations. Lastly, our fully automatic arch strappers are for in-line use and require no operator.

The machines offer a completely automatic loading, feeding, chamfering and length measuring processes. Using an absolute length measuring system (against a calibrated piece), the machines may also be programmed to stop after a certain number of pieces do not fall within the specified length tolerance. This is suitable for a clean and even chamfer on both ends of the tube, with chamfering the inside + outside (I/O) and face of the material or making a radius (round) chamfer than measuring its length. It may also be used for outside chamfering of solid bars

HYDROTEST

HYDROTESTING Gallium offers Single/Triple tube Hydrotesters equipped with oil/water high pressure (up to 5000 psi) intensifiers, automatic handling systems and chart

type pressure recorders according to API/ASTM/BS standards.

ไทย

ไทย English

English