Julia’s R&D department, together with the biggest machine producer, has carried out an extensive study of the cutting process of toilet paper. Our goal was to develop an innovative log saw blade with a special profile that could reduce the friction and the temperature during the cutting process.

Now we are happy to offer a special product with a new axial geometry and an excellent smooth surface. This new profile, combined with very low axial and radial run out, engraved on every single blade, enables exceptionally clean cuts and the best cutting performance together with a long knife life. Our blades are designed for high speeds up to 300 strokes per minute. Our log saw blades are designed to cut toilet paper, kitchen paper, and many more tissue items. These knives can be used on the following tissue saw machines: Fabio Perini, PCMC, Gambini, Futura, MTC, United Converting, Maflex, MTorres Tissue, Bretting, BaoSuo, Italconverting, Kawanoe Zoki, Dechangyu, Zambak Kagit. Julia can also offer the correct grinding wheels for all types of machines to grind our high hardness knives.

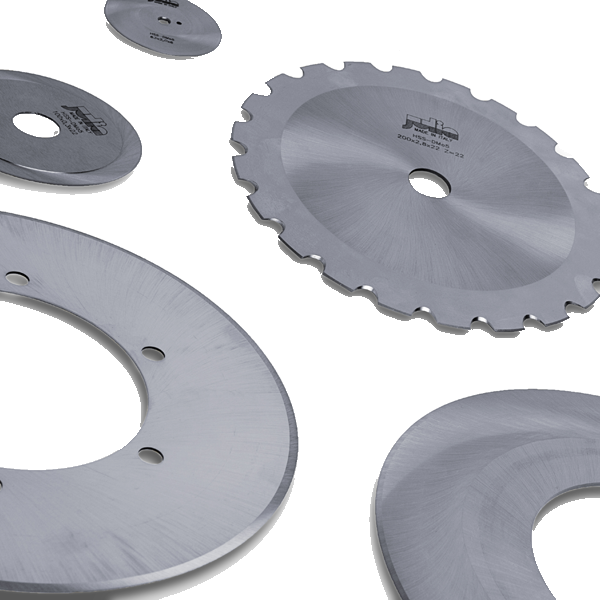

The extensive variety of knives we produce for various applications range from a minimum diameter of 25 mm to a maximum of 700 mm and provide specific solutions for any cutting job.

We have been manufacturing knives for over thirty years, to cut a great variety of materials, such as carton, plastic, rubber, cork, deep frozen goods, rubber pipes with or without metallic weft, carton tubes and foams. To obtain the best result it is important to define the required features of the tool. The knife material depends on what is being cut and on the customer’s productivity needs.

Julia uses different steels which offer a wide range of solutions for all these applications. Knife shape is very important; standard shapes for ordinary applications are defined from the kind of sharpening, which can be single or double bevel.

The circular knives are usually sharpened like a linear blade knife, and can be with or without teeth depending on the materials they have to cut. Technical advances in blade geometry and the experience we have acquired across several applications show that for some materials a specific tooth type or a particular notch considerably increase cutting performance. We normally manufacture knives to specific customer designs.

SHAPES AND APPLICATIONS

Description | Form | Application | Example |

Double bevel | Plastic tubes and | ||

Sharpened | Cardboard tubes, toilet | ||

Sharpened | Aluminium, foil, adhesive | ||

Single bevel | Packaging material, |

Index

D : Knife diameter | d : Bore diameter | L : Bevel length | α : Bevel angle | F : Pre-bevel length | β : Pre-bevel angle |

CIRCULAR KNIFE PROFILES AND TEETH LAYOUT

Circular knives are usually sharpened like a blade knife, teeth being unnecessary because of the materials they have to cut. Technical advances in blade geometry and the experience we have acquired during innumerable applications show that for some materials a specific tooth type or particular notch considerably increases cutting performance. In the following chart we have highlighted some of the possible geometries and their applications

English

English