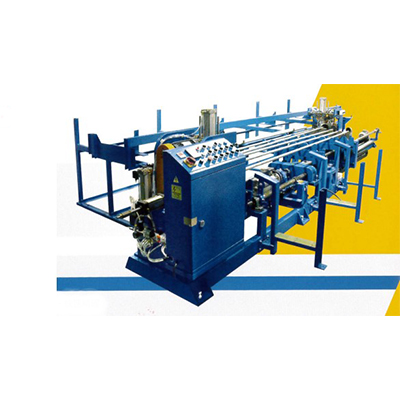

C-60-4AL

FEATURES

1. The round tube can be repaired inside, outside and repaired at one time, fast and precise

2. The cutter head uses a commercially available blade, which is easy to replace.

3. Two-stage feeding, the air stroke is smooth, and the working stroke can be adjusted stably according to the amount of cutting.

4. With manual and automatic function, it is convenient to adjust and adjust the machine

5. Special automatic positioning device, which can automatically position, feed and chamfer, and fine-tune the length tolerance

6. Oil mist lubrication cooling system can increase blade life without chipping

7. The machine of the processing length can be divided into two kinds of A.600mm ~ 3000mm B. 1000mm ~ 6000mm

STANDARD ACCESSORIES

1. Main machine unit & Transmitting system

2. PLC control system

3. Hydraulic system

4. Standard insert head*2 pcs(including insert holder and insert)

5. Clamp*1 set

6. Insert clamping wrench

7. Tool box

8. Cutting oil spray system

MODEL | C-60-4AL | CH-100-2A2 / CH-100-2A3 |

Motor | 2HP*2 | 3HP(4P)*2/3HP(4P)*3 |

Speed | 4P(2500/1430) 6P(1740/1000) | 4P(930/730) |

Working Length | A:600~3000mm or B:1000~6000mm | 100~320mm |

Pipe O.S. | 012~860mm | 20~120mm |

Working Pressure | 6-8 kg/cm2 | 6-8 kg/cm2 |

Machine Dimensions(mm) | 3米:3155x5000x1400mm/6米:3155x8000x1400mm | 2200x1550x1800mm |

Machine Weight(Kg) | 3米:1800kgs/6米:2000kgs | 1800kgs |

Hydraulic Motor | 3HP |

CH-100-2A2, CH-100-2A3

FEATURES

1. The cutter head uses a commercially available blade, which is easy to replace.

2. Two-stage feeding, the air stroke is smooth, and the working stroke can be adjusted stably according to the amount of cutting.

3. With manual and automatic function, it is convenient to adjust and adjust the machine

4. Oil mist lubrication cooling system can increase blade life without chipping

5. This machine is used for facing elbow, 45 degree elbow and tee, and can also be used for facing after bending.

STANDARD ACCESSORIES

1. Main unit and transmission system

2. PLC automatic electronic control system

3. Insert head*2 pcs(including insert holder and insert)

4. Tool box

ไทย

ไทย English

English