Shark 420 CNC HS 4.0, automatic double-column bandsaw for 0° cuts on structural, stainless and alloy steels, profiles and solid parts, with dimensions up to 420×420 mm.

เครื่องเลื่อยสายพาน SHARK 420 CNC HS 4.0

– CNC machine with a new controller: MEP 40. It has been specifically designed by MEP for the automation of its range of products

– This sawing machine also features a semiautomatic cutting cycle and uses latest generation technologies; indeed, Shark 420 CNC HS 4.0 is equipped with a NEW controller with processor RISC 32 bit 200 MHz with integrated interface to:

– Install a GSM card (OPTIONAL) to send an SMS to the programmed number notifying the type of emergency occurred while the machine was operating unattended.

– Connect to an Ethernet network for the remote assistance service.

– Get software updates and changes by e-mail, that are transferred to USB port by SD or MMC card and later on the control memory, through the suitable slot on the control console.

– Choose in the library (that can be extended by the user) the material type, geometry and hardness, the type of band to be used and the control automatically sets the feed rate and the band rotation speed.

OTHER FEATURES

- The limits of the head stroke are programmed through the console, depending on the dimensions of the bars to be cut.

- CNC machine to store up to 300 cutting programs each with different quantity and length.

- Structure in sturdy cast iron, to absorb vibrations and give the machine a better cutting stability and longer blade life.

- Saw frame movement with a brushless motor and with recirculating ballscrews-nut, with hydraulic compensation of the cutting head.

- The head movement by means the linear guides with ball-recirculating pre-charged slides.

- Hydraulic power pack to supply the feeding and cutting vices.

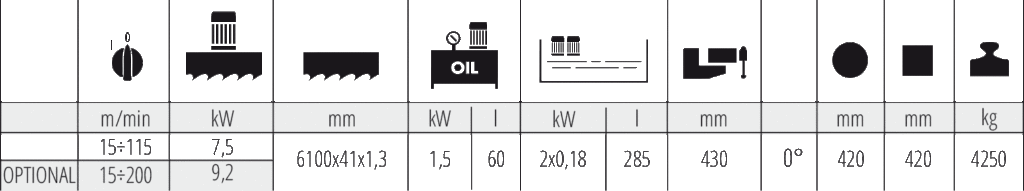

- Infinitely adjustable cutting speed from 15 to 115 m/min by vector inverter.

- Bar feeder with recirculating balls screw/nut and stepper motor, (feeding length in one stroke 600 mm, that can be repeated in order to cut any length).

- Self-aligning feeder vice unit for feeding even strained bars.

- Minimum bar remnant of 120 mm in automatic operation. (OPTIONAL feeder jaws to reduce the remnant to min. 25mm)

- Driving and idler pulley locked by conical clamping ring to ensure a strong fastening.

- Software to control/assess/correct in real time:

- Cutting force – cutting torque and band tensioning against the programmed values.

- Low voltage control panel installed on a rotating arm to reach the positions to operate safely stillkeeping the visual control.

- 8” touch screen display operator interface and push buttons for all functions of the sawing machine. It is simple and intuitive , with a self-learning feature it guarantees a reliable use and it controls all cutting parameters in real time.

- Adjustable blade-guide heads in steel, with roller and carbide pads, coolant taps for the traditional lubrication and preset to install the mist lubrication (OPTIONAL).

- Idler pulley movement from the keyboard to replace the band easily.

- Automatic adjustment of the front blade-guide head according to the dimensions of the bars to be cut.

- Blade deviation device.

- Laser projector to position the bar accurately to carry out non-standard or facing cuts.

- Band rotation control with stop in real time in case of blade jammed.

- Electro-mechanical servo-system for the blade dynamic tensioning.

- Coolant tank incorporated in the base.

- Two coolant pumps to ensure high coolant flood (120 l/min) to cool down the band and wash up chips from the working area, so as to guarantee a longer blade life.

- Wash gun to clean the working area.

- Powered blade brush.

- Chip conveyor.

- Sound and flashing indicator for machine alarms.

- Machine preset for being handled also with lift truck.

- Bimetallic band for profiles and solid pieces.

- Service keys and instructions manual, for maintenance and spare parts list.

ไทย

ไทย English

English